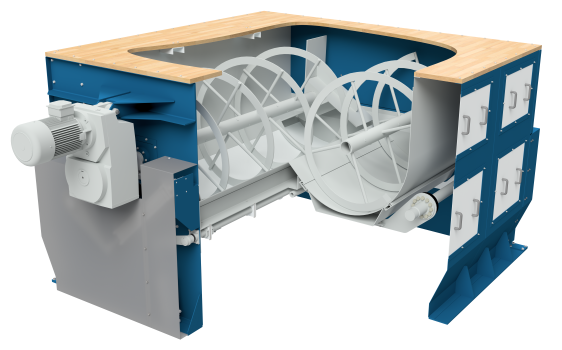

Horizontal Batch Blenders type RDM 2000 / 4000 / 6000 / 8000 / 12000

- Mixtures of all dry, grainy and free flowing products (grass seeds, cereals, pulses, etc.)

- No product damage and optimal homogeneity

- Solid steel construction for low wear and maintenance

- Easy cleaning and access to all parts

- 5 types with 2.000 - 12.000 liter capacity (other types on request)

Standard construction

- Two shafts with counter-rotating spirals, each one with drive motor

- End bearing assemblies with double shaft sealing

- Two-part, pneumatic bottom flap below the entire mixing chamber for fast and residue free discharge

- Frictional connection for flexible adjustment of discharge flap position

- Heavy-duty mixing chamber

- Completely closed, dust-proof housing for hygienic and clean operation

- Aspiration spouts

Optional

- Food safe design (FDA) with stainless steel mixing chamber

- Support / Platform (static or mobile), optional with control pedestal

- Feed hopper, discharge hopper

- Conveyor equipment (belt conveyors, bucket elevators, continuous bucket elevators, etc.) for feeding and discharging